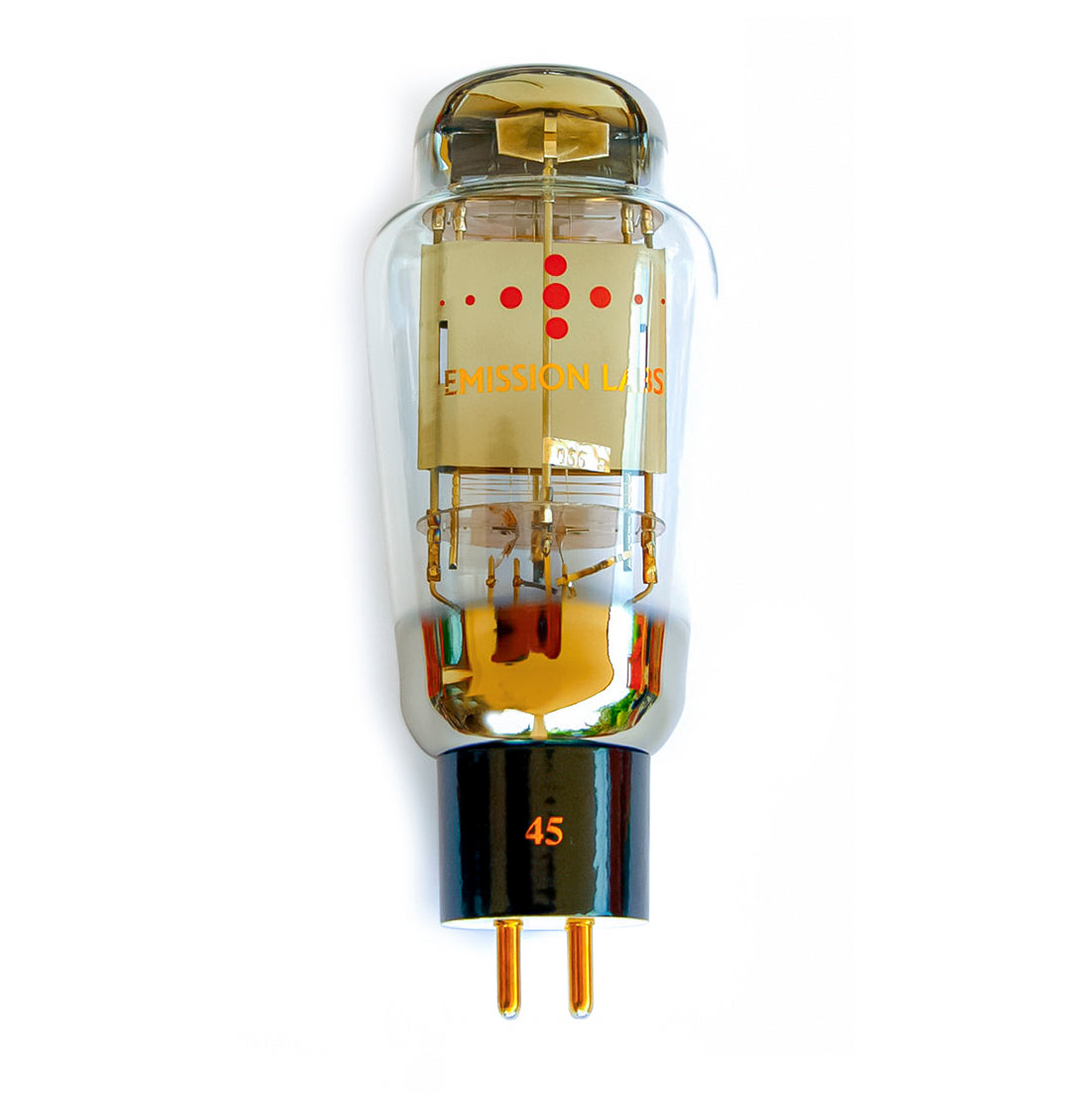

High quality Teflon sockets

Sockets for both UX-type and UV-type vacuum tubes

Compatible Vacuum Tubes

300B, 2A3, 45, WE205D, WE101D, WE104D

Mounting hole 30φ, screw interval 38.2mm

Enables replacement of WE205D and China-made 205D, etc.

The original tube socket is made of fluorocarbon resin (or COMPLITE), and a round machined pin is fixed to it. This prevents deterioration of sound quality due to vibration, since the tube is held firmly without rattling. The excellent insulating property of fluoroplastic also makes it a key component in the construction of vacuum tube amplifiers.

Explanation of materials used

Fluoroplastic: Official name is ethylene tetrafluoride, which has the highest electrical insulation and dielectric constant of any solid. It also has excellent temperature resistance characteristics.

COMPLITE: A material made by forcibly drying wood and impregnating it with phenolic resin as a base material, which has the same electrical properties as Bakelite but superior strength. It also has high heat resistance, and its high strength enables it to produce a firm sound.

Phosphor bronzePhosphor bronze is used as the material for pins in most tube sockets (except for the L series). It has high strength, excellent springiness, and maintains stable contact.

Gold plating: Thick gold plating is applied to most socket pins over a non-magnetic base material. (Except for the L series) Magnetic materials are also eliminated from the plating as much as possible.